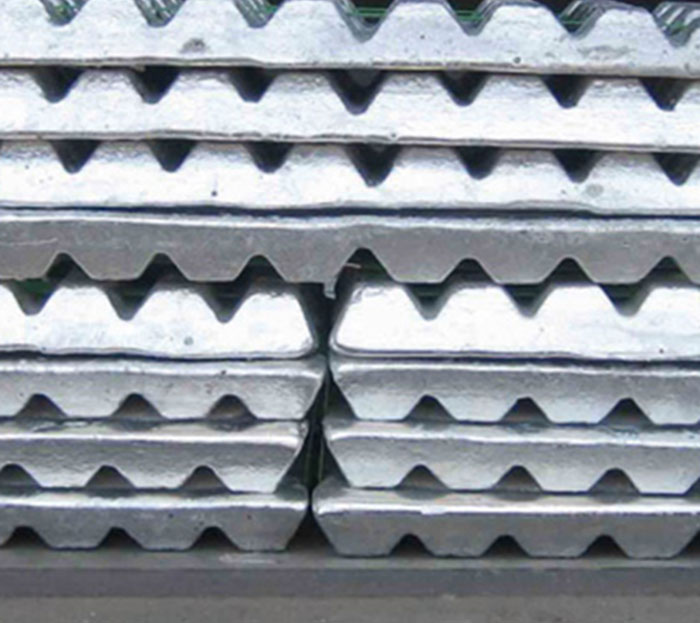

Aluminum-based master alloy ingot

A traditional product mainly used by aluminum intermediary companies to adjust the composition of aluminum melts. It is a metal element with a higher melting temperature. It uses the complex melting method and aluminum production intermediates. The melting temperature of this intermediate is significantly reduced, so that some metal elements with a higher melting temperature are added to the aluminum liquid at a lower temperature to adjust the element content of the aluminum melt.

◆ Features

The composition is uniform and the melting temperature is low.

Easy to break and easy to join.

The ingredient content is high and it is easy to absorb.

◆ Usage and dosage

According to the required control standard of the elements in the melt and the standard content of the master alloy, the amount of master alloy required to prepare the total amount of the melt is calculated

Generally used to adjust the composition. Add the master alloy charge together and spread it evenly in the middle of the charge.

After the melt is melted, stir it evenly, and take samples for analysis.

◆ Packaging and storage

Heye ingots are all supplied according to national standards, and every four mirrors is a circle, and one piece has a net weight of about 25 kilograms.

The front of the alloy ingot has the alloy code and the number of the 8th batch of production.

Store in a dry warehouse.

Take a sample for the laboratory test, take any one piece, and take three points from the upper surface (smooth surface) of the alloy ingot along the diagonal aluminum and mix them for processing and analysis.

EN

CN

EN

CN